Last fall, the DVD+RW Alliance dropped a bombshell on the optical storage industry when they announced Double Layer DVD+R technology. Developed by Philips Research and MKM (Mitsubishi Kagaku Media), this new technology increases the capacity of DVD+R media from 4.7GB to 8.5GB. While not quite double the capacity, it does allow users to store up to 8.5GB of data, 4 hours of DVD quality video or 16 hours of VHS quality video without the need to flip over the disc.

Before this, the concept of double layer recordable media was nothing more than a pipe dream. While double layer DVD-ROM's have been around for a number of years, there were a number of things that kept this technology from being applied to recordable media. One hurdle in particular was the media itself. How do you keep one layer from interfering with the other while recording? More importantly, how do you ensure that the discs will be playable on most existing DVD players?

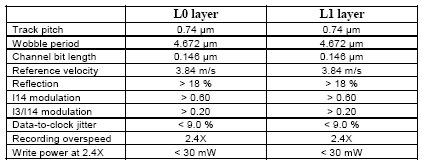

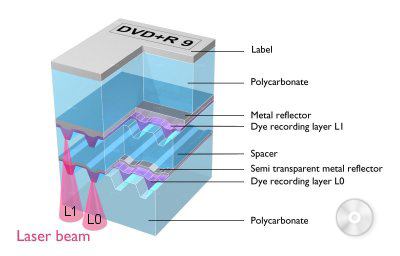

Finding answers to these questions wasn't easy. It took Philips two years to work out the details and that was with the help of MKM. The eventual solution was to use two organic dye recording layers, separated by a transparent spacer, about 55µm thick. The first, or lower, recording layer (L0) is backed by a thin silver-alloy. This semi-reflective metal has a reflectivity of about 18%, keeping it in compliance with the double layer DVD-ROM standard. This layer also lets the laser beam pass through so it can focus on the second, or upper, layer (L1). Because the first layer absorbs and reflects about half of the laser's power, the second layer has higher power sensitivity and greater reflectivity (> 50%). Even then, the effective reflection is only about 18%, the same as the first layer.

Double layer DVD+R discs also use a wobbled pre-groove to control the rotation speed and provide the addressing information. While single layer discs have this molded into the polycarbonate base, each layer has their own wobbled pre-groove. When a double layer disc is inserted into a drive, the laser will focus on one of the layers and try to detect the ADdress In Pre-groove (ADIP) signal. With this, the drive can determine the number of layers and, if it's a double layer disc, which layer it has focused on. From here the drive will try to determine whether or not the disc is blank, partially recorded, or finalized.

The recording process is also a little different with double layer DVD+R media, but we'll touch on that later in this article. For now, let's take a brief look at Sony's new double layer DVD writer, the DRU-700A.